-

G0602 gears - more with Powershell

A practical exercise with PowerShell.

6 gears with 2 gears of a set of 10 available gears make up the ratio for cutting metric and imperial threads using a G0602 metal lathe.

The gear labels suggest only 24 metric and 29 imperial combinations, but 526 unique combinations from 0,25mm/101,6tpi up to 3,47tpi/7,3169mm are possible.

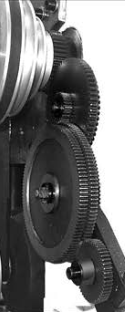

Gears

The spindle gear at the top all the way down to the leadscrew gear at the bottom:

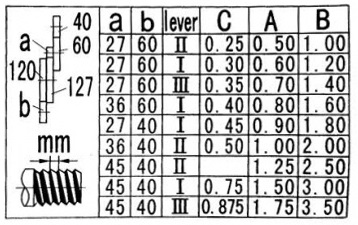

The leadscrew gear

The leadscrew gear allows 9 different ratios:

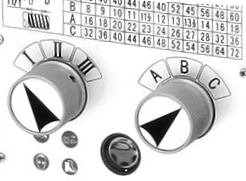

Imperial gear label

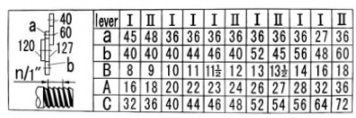

Metric gear label

The script

This PowerShell script creates all gear combinations and outputs the result in a CSV and TXT file. The CSV contains also all duplicate combinations possible with the different gear ratios.

First all gears combinations are created from a one-dimensional array into a two-dimensional array. The ratios of all gear combinations are connected to the 9 leadscrew ratios. The a and b gear are swapped in the inner loop.

The result is stored in one of PowerShells best inventions: the PSCustomObject. The result of the calculation is a list of PSCustomObjects which can be send directly to a CSV or formatted to a TXT file.The lead screw has 12 threads per Inch. The conversion from Inch to metric is done by connecting the 'b' gear to the 120 gear instead of the 127 gear.

2 * 127 = 254 -> 1 Inch = 25.4 mm

With the leadscrew gears (III,ABC), the main ratio is a/b IIIABC. For metric it is 4/3 ratio and 18 / ratio for imperial.

For each of the values, the matching metric/imperial value is added in brackets. The conversion is rather simple: Metric = 25.4mmtpi / Imperial and *Imperial = 25.4tpimm / Metric**

# available gears $z = @(27, 32, 36, 40, 44, 45, 48, 52, 56, 60) $ab = $null # create all gear combinations for ([int]$u = 0; $u -lt $z.length; $u++) { for ([int]$v = $u+1; $v -lt $z.length; $v++) { $ab += ,($z[$u], $z[$v]) } } # leadscrew gear ratio $ABC = @((1,'A'),(2,'B'),(0.5,'C')) $III = @((1,'I'),((5/6),'II'),((7/6),'III')) $t = foreach ($_ab in $ab) { foreach ($_A in $ABC) { foreach ($_I in $III) { # and swap gear for ([int]$ab_index = 0; $ab_index -lt 2; $ab_index++) { $a = $_ab[$ab_index] $b = $_ab[1-$ab_index] $r = $_I[0] * $_A[0] * $a / $b $mm = $r * 4 / 3 $tpi = 18 / $r [PSCustomObject]@{ 'a' = $a 'b' = $b 'III' = $_I[1] 'ABC' = $_A[1] 'mm' = $mm 'tpi' = $tpi } } } } } # export to CSV $t | Export-Csv -NoTypeInformation -Delimiter ";" -Encoding UTF8 -Path g0602.csv # sort for threadsize and write to a text file $list = $t | sort -Property mm -Unique | % { (" {0}-{1} {2,-3} {3} = {4:0.####}mm ({5:0.##}tpi) {6:0.##}tpi ({7:0.####}mm) " -f $_.a, $_.b, $_.III, $_.ABC, $_.mm, (25.4 / $_.mm), $_.tpi, (25.4 / $_.tpi)) } $list | Out-File g0602.txt $list "{0} Einträge" -f $list.Count

Most combinations are fractional. Here is a filtered metric list (24 entries):

$list_mm = $t | sort -Property mm -Unique | ? { (20*$_.mm - [int](20*$_.mm)) -eq 0 } | % { (" {0}-{1} {2,-3} {3} = {4:0.####}mm ({5:0.##}tpi) " -f $_.a, $_.b, $_.III, $_.ABC, $_.mm, (25.4 / $_.mm), $_.tpi, (25.4 / $_.tpi)) } 27-60 II C = 0,25mm (101,6tpi) 27-60 I C = 0,3mm (84,67tpi) 27-40 I C = 0,45mm (56,44tpi) 36-40 II C = 0,5mm (50,8tpi) 27-60 I A = 0,6mm (42,33tpi) 45-40 I C = 0,75mm (33,87tpi) 27-40 I A = 0,9mm (28,22tpi) 27-36 I A = 1mm (25,4tpi) 27-40 III A = 1,05mm (24,19tpi) 27-60 I B = 1,2mm (21,17tpi) 36-32 II A = 1,25mm (20,32tpi) 27-48 I B = 1,5mm (16,93tpi) 36-32 III A = 1,75mm (14,51tpi) 27-40 I B = 1,8mm (14,11tpi) 36-48 I B = 2mm (12,7tpi) 27-40 III B = 2,1mm (12,1tpi) 27-32 I B = 2,25mm (11,29tpi) 36-40 I B = 2,4mm (10,58tpi) 45-56 III B = 2,5mm (10,16tpi) 36-32 I B = 3mm (8,47tpi) 36-32 III B = 3,5mm (7,26tpi) 45-32 I B = 3,75mm (6,77tpi) 48-32 I B = 4mm (6,35tpi) 60-32 I B = 5mm (5,08tpi)

Filtered imperial list (56 entries):$list_tpi = $t | sort -Property mm -Unique | ? { (2*$_.tpi - [int](2*$_.tpi)) -eq 0 } | % { (" {0}-{1} {2,-3} {3} = {6:0.##}tpi ({7:0.####}mm) " -f $_.a, $_.b, $_.III, $_.ABC, $_.mm, (25.4 / $_.mm), $_.tpi, (25.4 / $_.tpi)) } 27-60 II C = 96tpi (0,2646mm) 32-60 II C = 81tpi (0,3136mm) 27-60 I C = 80tpi (0,3175mm) 36-60 II C = 72tpi (0,3528mm) 32-60 I C = 67,5tpi (0,3763mm) 27-40 II C = 64tpi (0,3969mm) 27-56 III C = 64tpi (0,3969mm) 32-56 I C = 63tpi (0,4032mm) 36-60 I C = 60tpi (0,4233mm) 32-52 I C = 58,5tpi (0,4342mm) 36-56 I C = 56tpi (0,4536mm) 36-45 II C = 54tpi (0,4704mm) 32-56 III C = 54tpi (0,4704mm) 36-52 I C = 52tpi (0,4885mm) 32-44 I C = 49,5tpi (0,5131mm) 36-40 II C = 48tpi (0,5292mm) 32-40 I C = 45tpi (0,5644mm) 36-44 I C = 44tpi (0,5773mm) 48-56 I C = 42tpi (0,6048mm) 48-45 II C = 40,5tpi (0,6272mm) 32-60 II A = 40,5tpi (0,6272mm) 27-60 I A = 40tpi (0,635mm) 48-52 I C = 39tpi (0,6513mm) 48-56 III C = 36tpi (0,7056mm) 48-44 I C = 33tpi (0,7697mm) 45-40 I C = 32tpi (0,7938mm) 27-56 III A = 32tpi (0,7938mm) 32-56 I A = 31,5tpi (0,8063mm) 48-40 I C = 30tpi (0,8467mm) 36-56 I A = 28tpi (0,9071mm) 60-45 I C = 27tpi (0,9407mm) 32-56 III A = 27tpi (0,9407mm) 36-52 I A = 26tpi (0,9769mm) 27-36 I A = 24tpi (1,0583mm) 32-40 I A = 22,5tpi (1,1289mm) 36-44 I A = 22tpi (1,1545mm) 48-56 I A = 21tpi (1,2095mm) 27-60 I B = 20tpi (1,27mm) 48-52 I A = 19,5tpi (1,3026mm) 27-45 II B = 18tpi (1,4111mm) 48-44 I A = 16,5tpi (1,5394mm) 27-48 I B = 16tpi (1,5875mm) 27-56 III B = 16tpi (1,5875mm) 36-60 I B = 15tpi (1,6933mm) 36-56 I B = 14tpi (1,8143mm) 48-36 I A = 13,5tpi (1,8815mm) 32-56 III B = 13,5tpi (1,8815mm) 36-52 I B = 13tpi (1,9538mm) 36-48 I B = 12tpi (2,1167mm) 36-44 I B = 11tpi (2,3091mm) 48-56 I B = 10,5tpi (2,419mm) 36-40 I B = 10tpi (2,54mm) 48-56 III B = 9tpi (2,8222mm) 36-32 I B = 8tpi (3,175mm) 48-40 I B = 7,5tpi (3,3867mm) 48-32 I B = 6tpi (4,2333mm)

All 526 entries as a text file sorted by size.

The metric column is the size with the 'b' gear connected to the 120.

The imperial column is the size with the 'b' gear connected to the 127.'a'-'b' leadscrew gear = metric column imperial column 27-60 II C = 0,25mm (101,6tpi) 96tpi (0,2646mm) 27-56 II C = 0,2679mm (94,83tpi) 89,6tpi (0,2835mm) 27-52 II C = 0,2885mm (88,05tpi) 83,2tpi (0,3053mm) 32-60 II C = 0,2963mm (85,73tpi) 81tpi (0,3136mm) 27-60 I C = 0,3mm (84,67tpi) 80tpi (0,3175mm) 27-48 II C = 0,3125mm (81,28tpi) 76,8tpi (0,3307mm) : : 60-27 II B = 4,9383mm (5,14tpi) 4,86tpi (5,2263mm) 60-32 I B = 5mm (5,08tpi) 4,8tpi (5,2917mm) 52-32 III B = 5,0556mm (5,02tpi) 4,75tpi (5,3505mm) 44-27 III B = 5,07mm (5,01tpi) 4,73tpi (5,3657mm) 52-27 I B = 5,1358mm (4,95tpi) 4,67tpi (5,4354mm) 45-27 III B = 5,1852mm (4,9tpi) 4,63tpi (5,4877mm) 56-32 III B = 5,4444mm (4,67tpi) 4,41tpi (5,762mm) 56-27 I B = 5,5309mm (4,59tpi) 4,34tpi (5,8535mm) 60-32 III B = 5,8333mm (4,35tpi) 4,11tpi (6,1736mm) 60-27 I B = 5,9259mm (4,29tpi) 4,05tpi (6,2716mm) 52-27 III B = 5,9918mm (4,24tpi) 4,01tpi (6,3413mm) 56-27 III B = 6,4527mm (3,94tpi) 3,72tpi (6,8291mm) 60-27 III B = 6,9136mm (3,67tpi) 3,47tpi (7,3169mm)

← Neuere Beiträge

Seite 8 von 8